About

Travis Joel Keener, PE (42 states*)

I've invested thousands of hours as a professional engineer on SPCC containment measurement and calculations. From rural oilfield pastures to some of the nation's largest cities. As an engineering consultant I measure and design compliant retrofits with the simplest means. I'm more concerned about containment capacity than most, that's probably why I have so many repeat customers.

Compliance Directed Engineering Surveys and Retrofit Designs

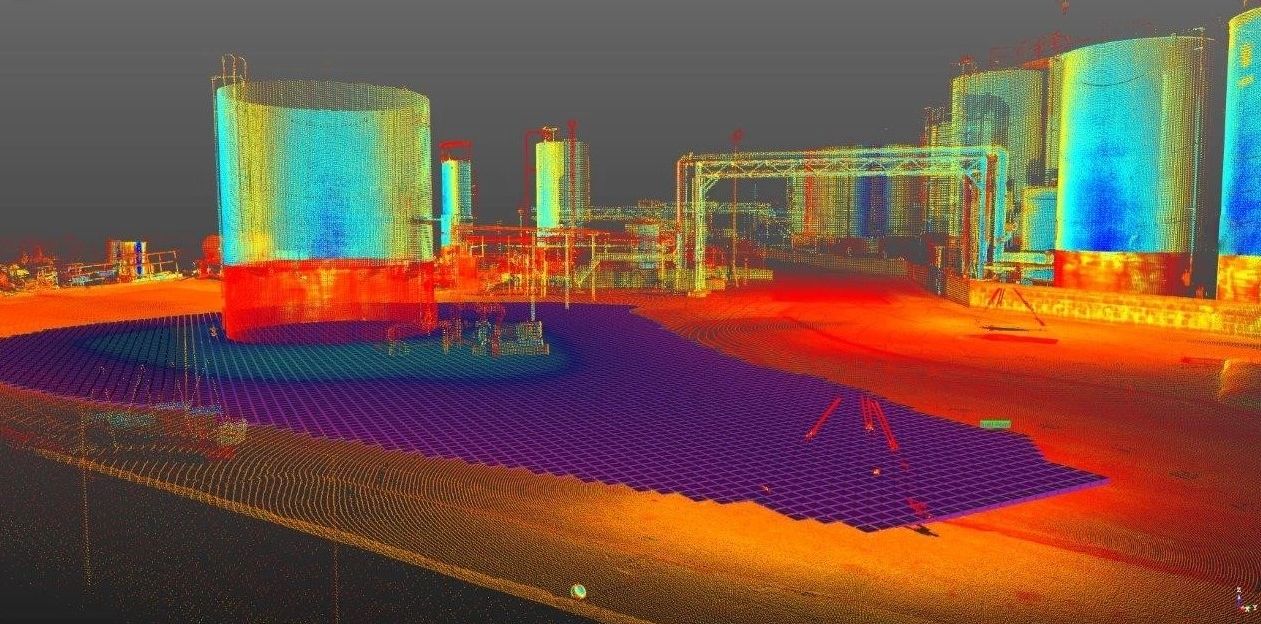

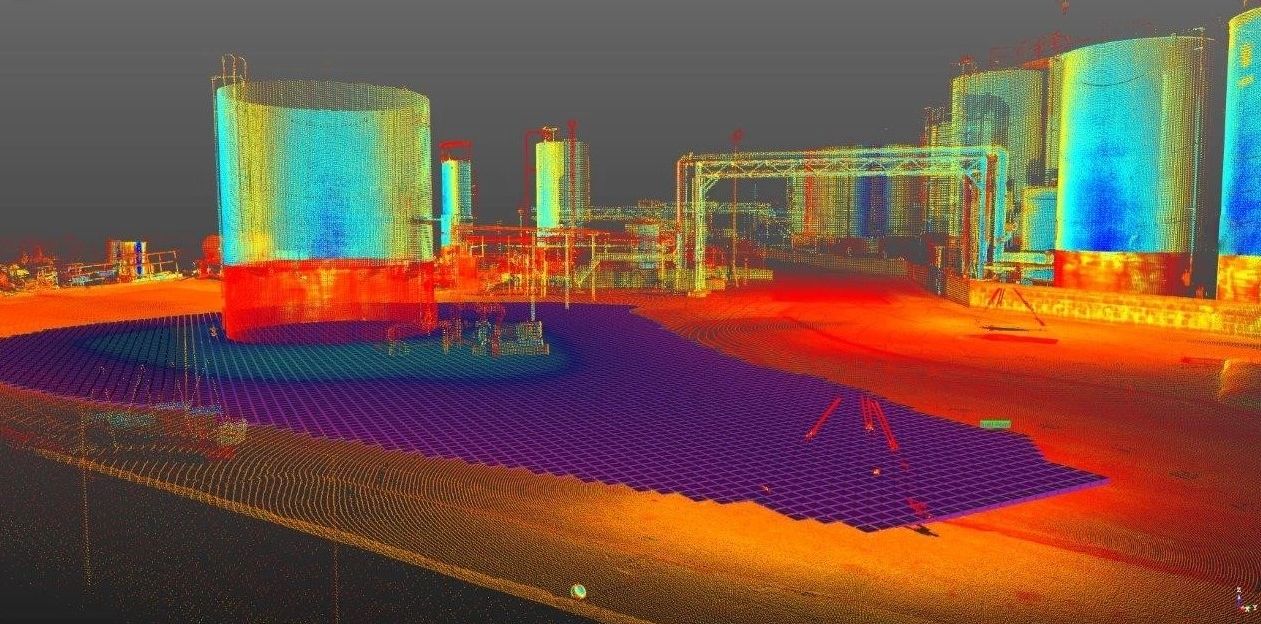

Airplane LiDar, Drone Photogrammetry, GPS, and 3D Laser Scans are fantastic depending on the job. But nothing beats human eyes searching diligently for the leak point in the top of the berm. Metal walkways and pipe racks can hide low spots from aerial technologies. Earthen to concrete wall transitions notoriously have dips / crevices that are easily missed without massive data saturation or a technician knowing where to look. Masonry walls can look great from a distance, but may have daylight showing through expansion joints and cracks upon closer inspection. 3D laser scanning collects millions of data points, but if decimated down for ease of use with volumetric software, the final surface model may triangulate or smooth right over the low spot, even though the raw 3D scanner data mapped it correctly. For each job site, it's good to confirm the lowest spot independent of the primary data acquisition method. Finally, the leak point in a containment system may ultimately be a pipe chase / sleeve, unknown drain line, or a porous floor.

LICENSURE MAP*

Frequently Asked Questions

Many times yes, some spot checks may be needed.

Yes, I can quote most jobs via desktop review.

Probably sooner than you are expecting.

Contact

Travis Joel Keener, PE

Call 918-766-9359

Mon | 09:00 am – 05:00 pm | |

Tue | 09:00 am – 05:00 pm | |

Wed | 09:00 am – 05:00 pm | |

Thu | 09:00 am – 05:00 pm | |

Fri | 09:00 am – 05:00 pm | |

Sat | Closed | |

Sun | 09:00 am – 05:00 pm |

Copyright © 2024 Containment - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.